The industrial automation sector is driven by a handful of dominant players. Among the most prominent names in this field are Siemens, Allen-Bradley, ABB, and Schneider Electric. These powerhouses have engineered cutting-edge technologies that have revolutionized manufacturing and industrial processes worldwide.

- Siemens is a worldwide conglomerate known for its extensive range of automation solutions, including PLCs, SCADA systems, and robotics.

- Allen-Bradley, a Rockwell Automation company, is highly regarded for its industrial control products, particularly its line of PLCs, which are widely used in multiple fields.

- ABB, a Swiss-Swedish multinational, specializes in industrial machinery, with a strong focus on electric vehicle charging infrastructure and renewable energy solutions.

- Schneider Electric, a French company, is a leader in energy efficiency technologies. Its portfolio includes automation equipment, circuit breakers, and software for building management systems.

These businesses continue to innovate at a rapid pace, shaping the future of industrial automation. Their commitment to quality has made them essential partners for businesses seeking to optimize their operations and achieve greater efficiency.

Comparing Industrial Control Systems from Leading Vendors

Industrial control systems produce a diverse range of functions, spanning industries such as energy. When selecting an ICS, it's essential to evaluate factors like scalability, reliability, and safeguard. Leading vendors in the ICS market provide a comprehensive range of solutions, each with its own benefits.

This article will contrast some of the most prominent ICS offerings from leading vendors, helping you make an informed choice.

A key element to review is the vendor's knowledge in your specific industry. Some vendors concentrate on particular sectors, such as automotive, while others offer more adaptable solutions.

Additionally, it's significant to consider the vendor's support offerings, including training, documentation, and service. A comprehensive support system can be invaluable in ensuring the smooth function of your ICS.

Allen-Bradley vs. Rockwell Automation: A Detailed Analysis of PLC Platforms

When it comes to industrial automation, selecting the right Programmable Logic Controller (PLC) platform is critical for success. Two prominent contenders in this arena are Siemens and Rockwell Automation, each offering a robust suite of features and capabilities. This comparative analysis delves into the strengths and weaknesses of these platforms, examining factors such as programming paradigms, hardware architectures, communication protocols, click here and application suitability.

- Allen-Bradley is renowned for its comprehensive range of PLCs, catering to diverse industry requirements from small-scale applications to large-scale, complex manufacturing environments.

- Allen-Bradley boasts a mature ecosystem with extensive industry support, readily available technical documentation, and a vast network of certified partners.

- The interoperability between hardware and software components within each platform is generally considered to be high, ensuring smooth operation and reduced troubleshooting efforts.

Neither platform offers advanced features such as motion control, safety functions, and data analytics capabilities. Ultimately, the ideal choice depends on specific project needs, budget constraints, and existing infrastructure.

A.B.B.'s Robotics Revolution: Transforming Manufacturing with Automation

ABB, a global leader in industrial automation, stands as at the forefront of the robotics revolution, completely transforming manufacturing landscapes worldwide. With its cutting-edge robotic solutions, ABB empowers businesses to maximize productivity, optimize processes, and promote a safer, more efficient work environment. From assembly lines to logistics hubs, ABB's robots carry out tasks with precision, speed, and reliability, releasing human workers from repetitive or hazardous duties.

- ABBs' collaborative robots, designed to work alongside humans, symbolize a new era of intelligent automation, where machines and people partner seamlessly.

- The company's comprehensive portfolio of robotics solutions includes industrial arms, mobile robots, and software platforms, serving the diverse needs of various industries.

ABB's commitment to innovation propels continuous advancements in robotics technology. Through strategic partnerships and dedicated research, ABB stays at the forefront of this transformative industry, shaping the future of manufacturing for years to come.

Schneider Electric's Smart Grid Technologies for a Sustainable Future

Schneider Electric is at the leading edge of the intelligent energy system revolution, providing cutting-edge solutions that optimize energy distribution. Their wide-ranging portfolio includes everything from advanced metering infrastructure to intelligent control systems, all designed to increase grid efficiency, reliability, and eco-friendliness. Through their partnerships approach with utilities, policymakers, and businesses, Schneider Electric is paving the way for a more efficient energy future.

This Evolving Landscape of Industrial Automation: Key Trends in 2023

Industrial automation is continuously transforming at a remarkable pace, with several key trends shaping the industry landscape in 2023. One prominent trend is the rise of collaborative robots, also known as co-bots, which are designed to {work{ alongside human operators, enhancing productivity and safety. Another significant development is the implementation of artificial intelligence (AI) and machine learning (ML) algorithms into automation systems, enabling smarter decision-making and process optimization. Furthermore, cloud computing is revolutionizing industrial automation by providing scalable infrastructure for data storage, processing, and interaction. These trends are propelling the industry toward a more productive future.

Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Danielle Fishel Then & Now!

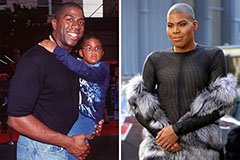

Danielle Fishel Then & Now! Earvin Johnson III Then & Now!

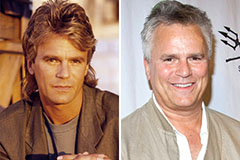

Earvin Johnson III Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!